Dimensional Control

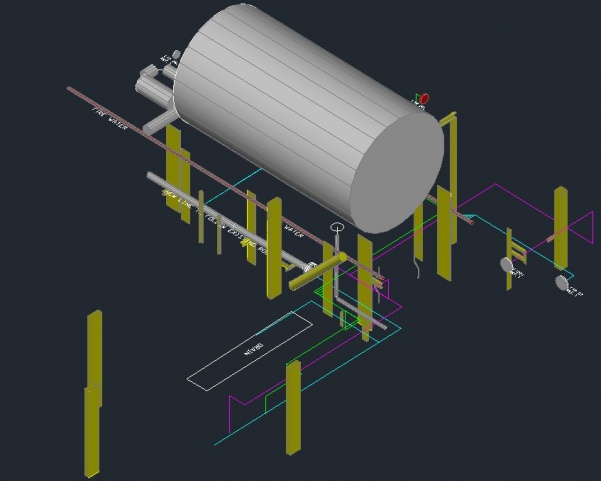

Dimensional Control (DC) surveying combines precise measurements and modelling of objects which are then compared with the original design. Data interpretation using the latest CAD software allows the surveyor to determine precise distances and angles bewtween points. DC surveying is predominantly associated with the oil and gas industry, where precise measurements are taken to ensure that everything fits, this is know in the industry as 'first-time fit'. Objects that are being replaced such as piping spools can be checked in the fabrication stage to ensure that they have been fabricated within the design tollerances before they are sent to their destination. Piping design routes can be surveyed to ensure there are no obstacles, this is know as 'clash checking'.

Ensuring that everyting fits first time has clear financial and health & safety benefits, with the elimination of 'hot-work' on site which can be problematic in the offshore industry.

Applications of Dimensional Control Surveying...

- Steel rail alignment (eg. crane rails).

- 'First time fit' solutions.

- Piping route surveys.

- Onshore and offshore pipe and tank surveys.

- 3D modelling and visualisation.

The combination of timely pre-planning and precise 3D measurements can ensure that objects such as steel components, piping spools and structures are fabricated within the design tollerances, and fit first time. Please get in touch if you have any dimensional control survey requirements.